What are ACPs?

Aluminum Composite Panels are sandwiched aluminium sheets around a polyethene core. They are comprised of either combustible or non-combustible thermoplastic material and are used in the interior and exterior of buildings. The primary purpose of the panels is to support the dead wall and provide aesthetics that elevate the look of the building.

|  |  |

What are they made up of?

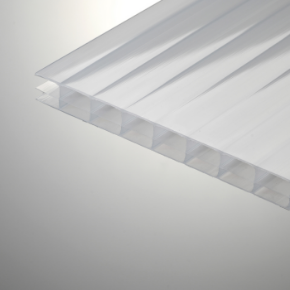

The composite panels are manufactured from two aluminium sheets well-bonded to a non-aluminium core. The top and bottom layers are of coated aluminium sheets and the core sandwiched between them is polyethene.

Here are some advantages of ACPs;

|

|

Types of Aluminium Composite thickness and their applications

Different applications have different thickness requirements for aluminium composite panels. Generally speaking, the common total thickness of ordinary aluminium composite panels is 3mm, 4mm and 6mm, etc. We provide only 3mm thickness with different variations of skin thickness of the aluminium foil.

_1000.png)

Sources: Alusignacm | Constrofacilitor