G

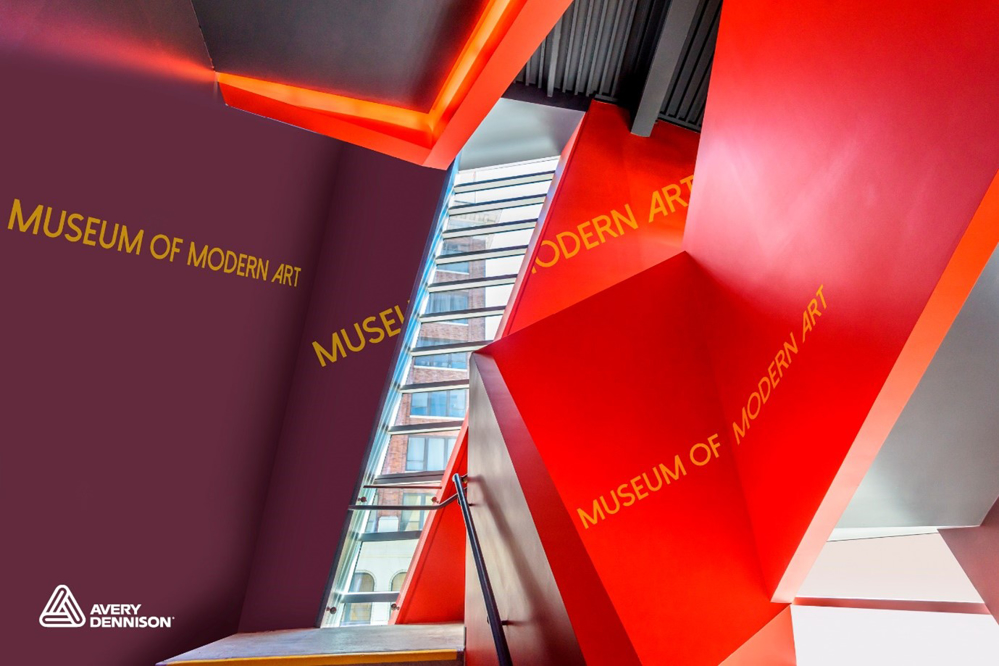

Sign Vinyl

Sign vinyl is a material that can be digitally cut into a shape or into letters that can adhere to different applications using adhesive on one side. ( walls, windows, signs etc.) The main advantage of using this method is its lifespan. You can expect about 5-10 years of expectancy, depending on its exposure to the sun.

On the other hand, there are limitations regarding the range of colours that can be used. There are also certain situations where the colours available won’t match the colour from the design or logo you are hoping to print. With sign vinyl, you cannot have fades or gradients in your colour, as this is a limitation.

If you can print your design in one or two colours, sign vinyl is the best option for you as the life expectancy is quite long, and it is a good quality option.

Some types of Sign Films:

- Opaque Sign Cut Films:

- Translucent Sign Cut Film:

o 5500 QM Translucent Film

o 4500 TF Translucent Film

- Window Graphics:

o Crystal Glass

- Reflective Films:

o V-2000

o V-4000

Digitally Printed Films

The limitations of sign vinyl are the advantage of digitally printed vinyl. Digital vinyl prints in full colour and can produce an extensive range of colours, including gradients and fades. This provides a wider range of possibilities with your design and signs and means there are no colour limitations.

Although, as stated with sign vinyl, the life span is quite long, whereas with digital vinyl, you can only expect around 2-3 years. This is due to exposure to UV rays and other exterior elements.

You can add a UV-resistant lamination on top, which will add two or three more years. Lamination can also be added to reduce the effects of scratches and water damage as this is also common.

Some types of Digital Printed Films:

- Promotional Solutions: Short term solutions for flat applications

Examples:

o MPI 3000

o MPI 3040

o SP 3523

- Specialities: Versatile special solutions for specific use cases, including architectural wall films, floor graphics, perforated window films and many more

Examples:

o MPI 6021

o MPI 8000

o SF 100

- High-Performance Solutions: High-performance and durable solutions for the most demanding 3D applications, including full vehicle wraps

Examples:

o MPI 1104

o MPI 1105

o MPI 1106

o SP 1504

- Intermediate Solutions: Premium long-term solutions on slightly curved surfaces, including vehicle graphics

Examples:

o MPI 2000

o MPI 2001

o MPI 2020

What is the difference between monomeric, polymeric and cast vinyl?

Monomeric Vinyl

Monomeric vinyl is best used for flat, indoor applications and can also be used for short-term outdoor applications. Short molecule plasticiser is added to monomeric vinyl which limits its flexibility and ability to mold. This produces short-term vinyl, which can be used for a vast array of flat applications and is generally quite inexpensive material. It has a short life span of about 2-5 years and does tend to shrink over time.

Why choose monomeric? | Why not? |

Ideal for flat, standard applications | Can suffer shrinkage over time |

Short to medium shelf life | It cannot be used for uneven surfaces |

Inexpensive |

Polymeric Vinyl

Polymeric vinyl is made using a longer chain molecule plasticiser, making it more flexible and reducing friction on the surface. This makes it easier to mold to specific shapes and can be used in various applications. It is best used for indoor and outdoor applications and has a medium-term life span of about 5-7 years. It is also less susceptible to shrinkage, making it more stable.

Why choose polymeric? | Why not? |

It can be used for more curved surfaces | It can cost more than monomeric |

Longer life span than monomeric |

|

Less shrinkage |

|

Cast Vinyl

Cast vinyl is produced by turning the ingredients that make up the finished vinyl into a paint-like substance with a solvent. This is then dried and cured at a high temperature, cooled and then rolled out very thin to make the flexible vinyl material. It is cured at a higher temperature than used during application, making it able to distort without degradation. It is a soft, thin and high-quality vinyl, making it perfect for vehicle wrapping. It has a life span of up to 10 years and will not shrink.

Why choose cast? | Why not? |

Very long life span | It can have higher costs than monomeric and polymeric vinyls |

Flexible, soft, and high quality |

|

Will not shrink |

|

Source: